Quality manufacturer supply Cellulose microcrystalline 9004-34-6 in stock with high standard

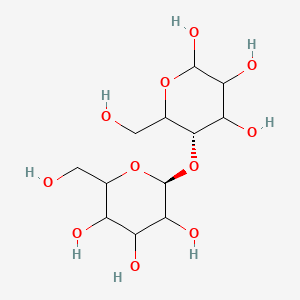

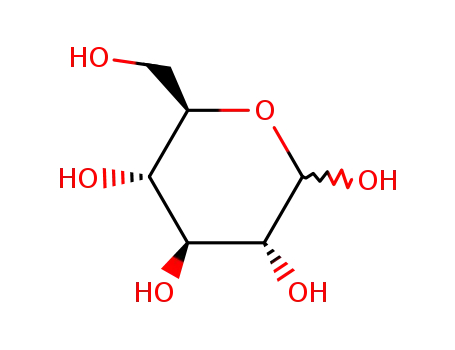

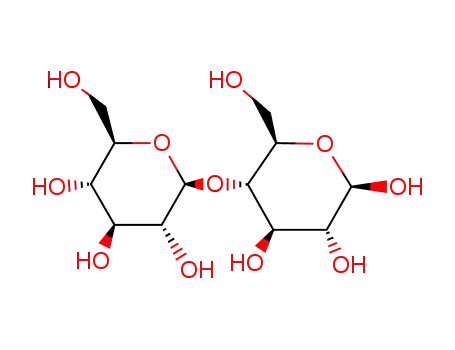

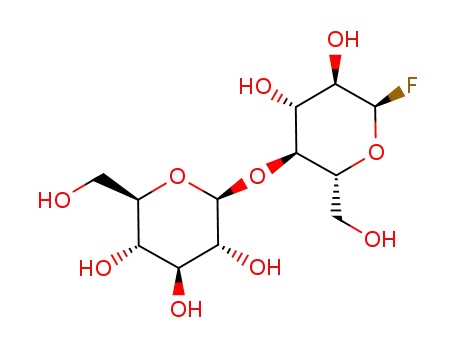

- Molecular Formula:(C6H10O5)n

- Molecular Weight:324.28

- Appearance/Colour:White crystal powder

- Vapor Pressure:1.08E-20mmHg at 25°C

- Melting Point:260-270oC

- Refractive Index:n20/D 1.504

- Boiling Point:667.9°C at 760 mmHg

- Flash Point:164oC

- PSA:0.00000

- Density:1.27-1.60 g/cm3 (20oC)

- LogP:0.00000

Cellulose microcrystalline(Cas 9004-34-6) Usage

Microcrystalline cellulose is a white, odorless, tasteless powdered substance. Microcrystalline cellulose is a term for refined wood pulp. In the pharmaceutical industry, it is often used as a filler, disintegrant and binder to help improve the stability and quality of drug preparations. In the food industry, it can be used as a source of dietary fiber to increase the nutritional value and taste of food. Microcrystalline cellulose is also widely used in cosmetics and other industrial fields.

InChI:InChI=1/C12H22O11/c13-1-3-5(15)6(16)9(19)12(22-3)23-10-4(2-14)21-11(20)8(18)7(10)17/h3-20H,1-2H2/t3?,4?,5?,6?,7?,8?,9?,10-,11?,12+/m1/s1

Jilin Tianyun New Materials Co., Ltd. is a professional production enterprise that production, processing, and export, mainly engaged in various organic chemicals. The company has a wealth of professional experience, reliable product quality, reasonable prices, and products are exported to countries around the world, which can meet your diverse needs. In our business cooperation with clients, we always adhere to the principle of equality and mutual benefit, and are deeply trusted and recognized by our clients. If you are interested in our company and our products, please feel free to visit our website or contact us directly for more information.We look forward to establishing a long-term stable and win-win business relationship with you.

9004-34-6 Relevant articles

A new protection group strategy for cellulose in an ionic liquid: simultaneous protection of two sites to yield 2,6-di-O-substituted mono-p-methoxytrityl cellulose

Granstr?m, Mari,Olszewska, Anna,M?kel?, Valtteri,Heikkinen, Sami,Kilpel?inen, Ilkka

, p. 1744 - 1747 (2009)

Increased reactivity of cellulose in ion...

Cellulose and microcrystalline cellulose from rice straw and banana plant waste: preparation and characterization

Maha M. Ibrahim, Waleed K. El-Zawawy, Yvonne Jüttke, Andreas Koschella & Thomas Heinze

, Cellulose, Volume 20, pages 2403–2416, (2013)

As part of continuing efforts to prepare cellulose and microcrystalline cellulose (MCC) from renewable biomass resources, rice straw and banana plant waste were used as the available agricultural biomass wastes in Egypt. The cellulose materials were obtained in the first step from rice straw and banana plant waste after chemical treatment, mainly applying alkaline-acid or acid-alkaline pulping which was followed by hypochlorite bleaching method.

Effect of cellulose microcrystalline particles on properties of cement based composites

Catalina Gómez Hoyos a , Emilien Cristia b , Analía Vázquez a

, Materials & Design Volume 51 , October 2013, Pages 810-818

The hydrophilic character and water retention capability of cellulose microcrystalline particles (MCC), are useful properties to achieve new developments in cement based materials. This work evaluates the influence of interactions between MCC, cement particles, hydration products and water; on rheology, hydration kinetic, microstructure and mechanical properties of cement based materials.

9004-34-6 Process route

-

Cellulose acetate

-

Cellulose acetate

-

cellulose

- 9004-34-6

cellulose

Conditions

| Conditions |

Yield |

|

With sodium hydroxide; In water; at 20 ℃; for 168h;

|

|

|

With water; at 20 ℃; for 168h; Alkaline conditions;

|

|

|

With water; sodium hydroxide; In ethanol; at 20 ℃; for 48h;

|

|

-

2,6-di-O-(4-methoxytrityl)cellulose

-

2,6-di-O-(4-methoxytrityl)cellulose

-

cellulose

- 9004-34-6

cellulose

Conditions

| Conditions |

Yield |

|

With iron(III) chloride; In dichloromethane; at 20 ℃;

|

100% |

9004-34-6 Upstream products

9004-34-6 Downstream products

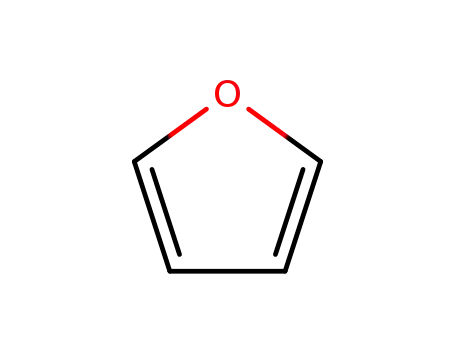

-

110-00-9

furan

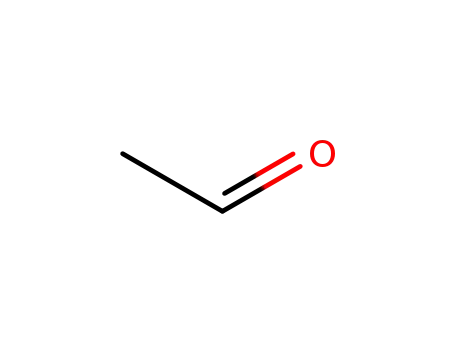

-

75-07-0

acetaldehyde

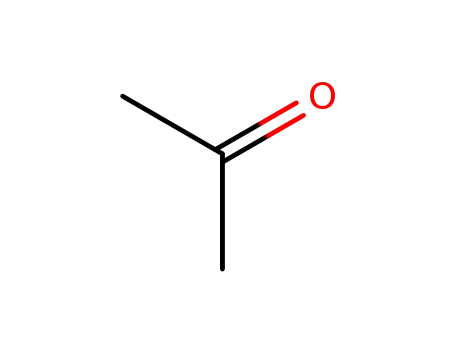

-

67-64-1

acetone

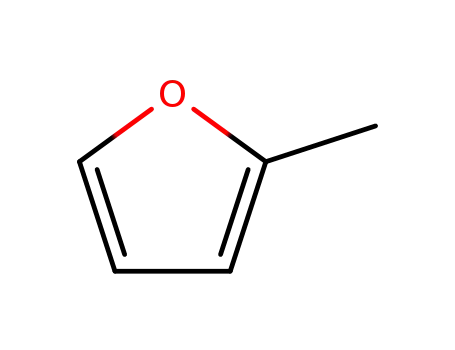

-

534-22-5

2-methylfuran